What Is the Best Diluent for Gel Coat: Acetone or Styrene?

First, it’s essential to distinguish whether the gel coat being sprayed is an epoxy gel coat or a polyester gel coat.

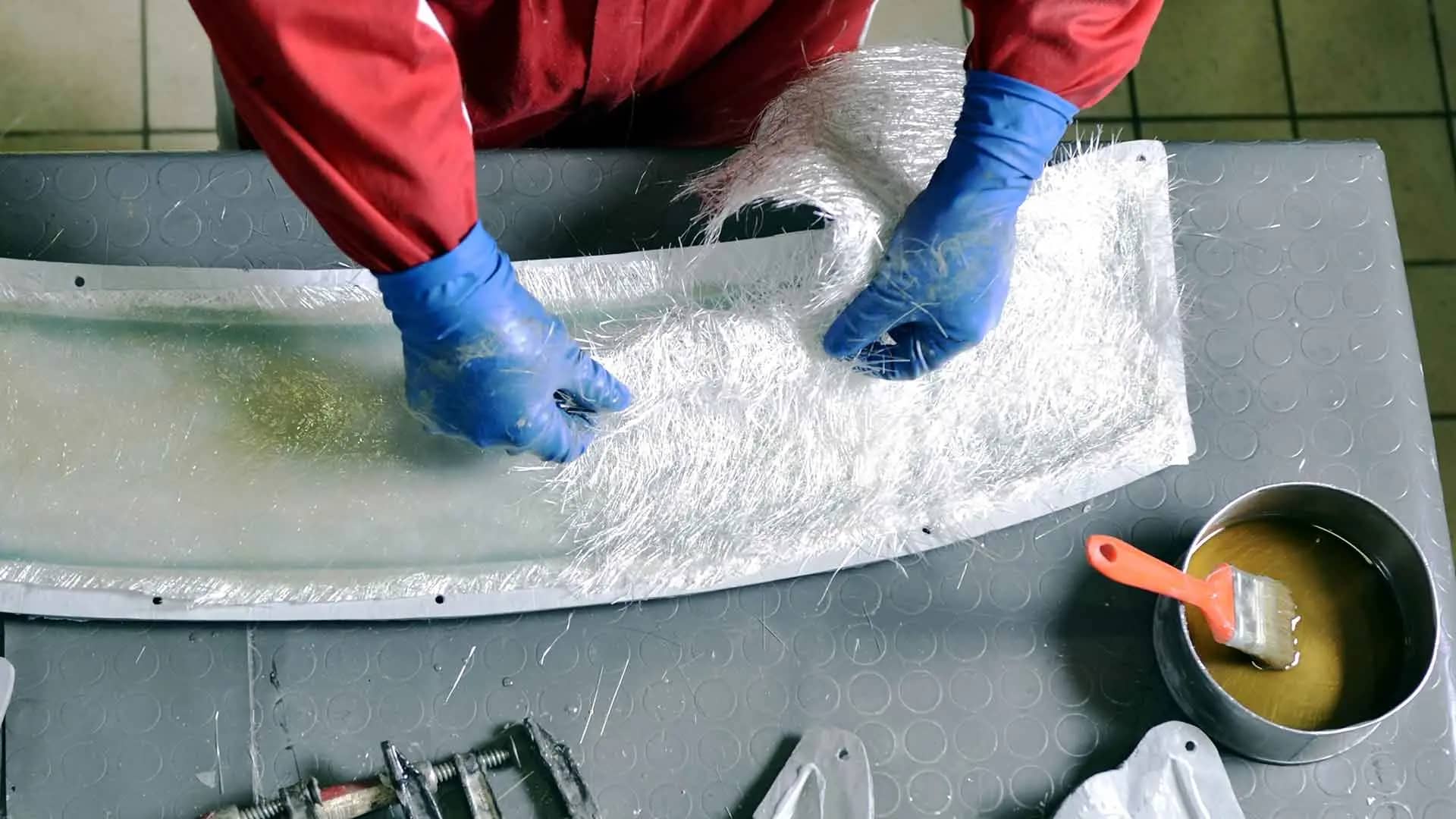

In the fiberglass industry, polyester gel coat is the most commonly used, encompassing vinyl ester mold gel coats, standard product gel coats, and various performance types, including easy-sanding gel coats and air-dry gel coats.

So, how do you choose between styrene and acetone?

For epoxy gel coats, acetone is the most suitable choice due to its excellent dilution properties, which can help save costs.

However, the focus of this discussion is on diluting polyester gel coats. Both acetone and styrene can be used for dilution, but styrene is preferred. This is because styrene is the main solvent in the gel coat and can participate in the cross-linking reaction, while acetone cannot. Additionally, acetone can introduce bubbles due to its volatility.

There’s a potential risk to consider. Most fiberglass workshops typically stock acetone for cleaning resin off tools but rarely keep styrene on hand. As a result, many people resort to using acetone for diluting gel coats, despite it not being the ideal choice.