01

Resin Impregnation

Fiber bundles pass through a resin impregnator or wet out device, completely saturating with resin.

02

Preforming

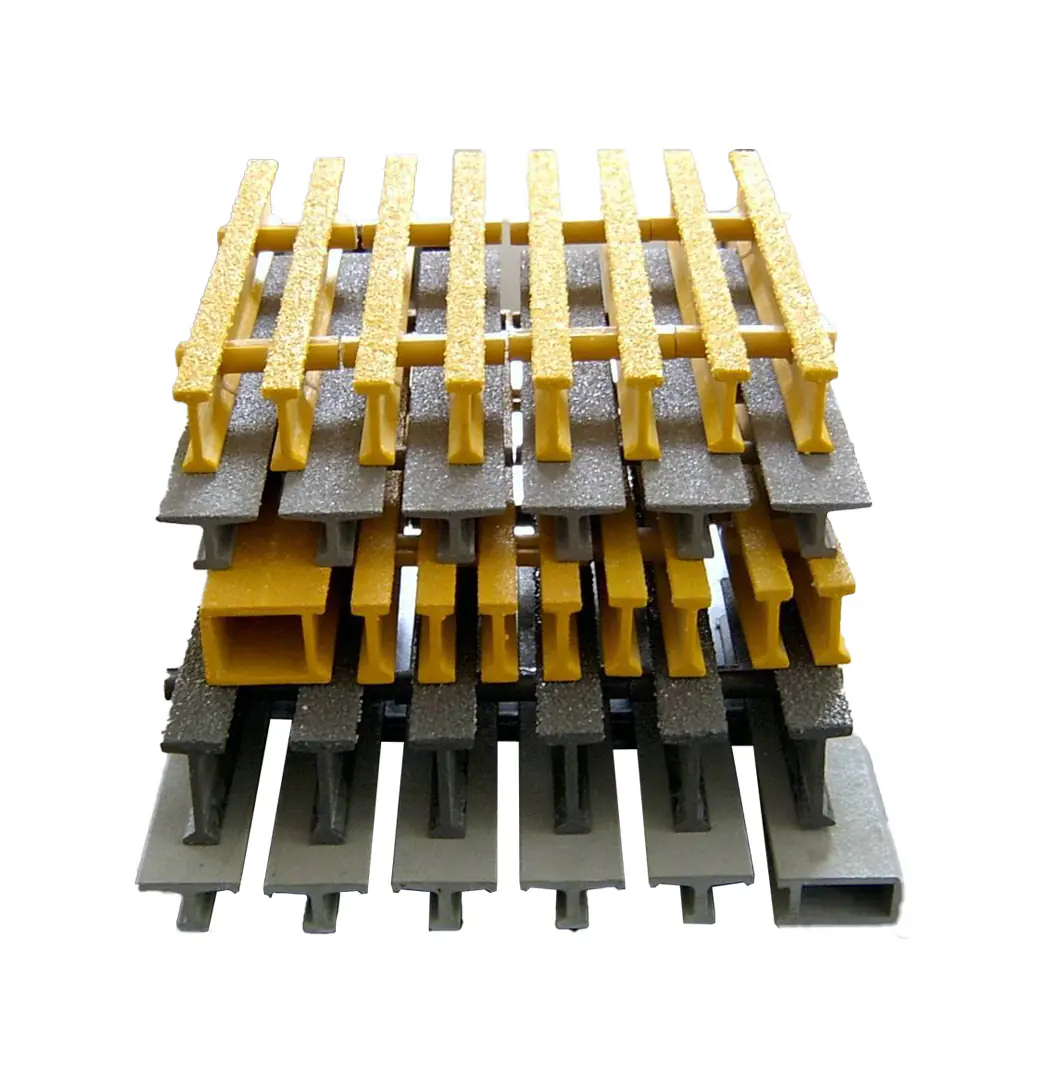

Impregnated fiber bundles pass through “preformer” tools to squeeze out excess resin and align fibers into the desired shape.

03

Steel Die Polymerization

Impregnated fibers pass through a heated steel die where the resin cures and solidifies into a hardened polymer.